STIMS Institute and MICROMATIC Grinding Technology Ltd (MGT) have been collaborating for more than eight years on an initiative to develop Unique New Solutions (UNS). These are solutions for new machine tools and their auxiliaries for novel grinding processes for customers. The goal is to focus on unique outcomes

not available in India and, in some cases, first of its kind in the world. The focus is always on the end to end innovation (i.e.) from concept to commercially realized or implemented solutions.

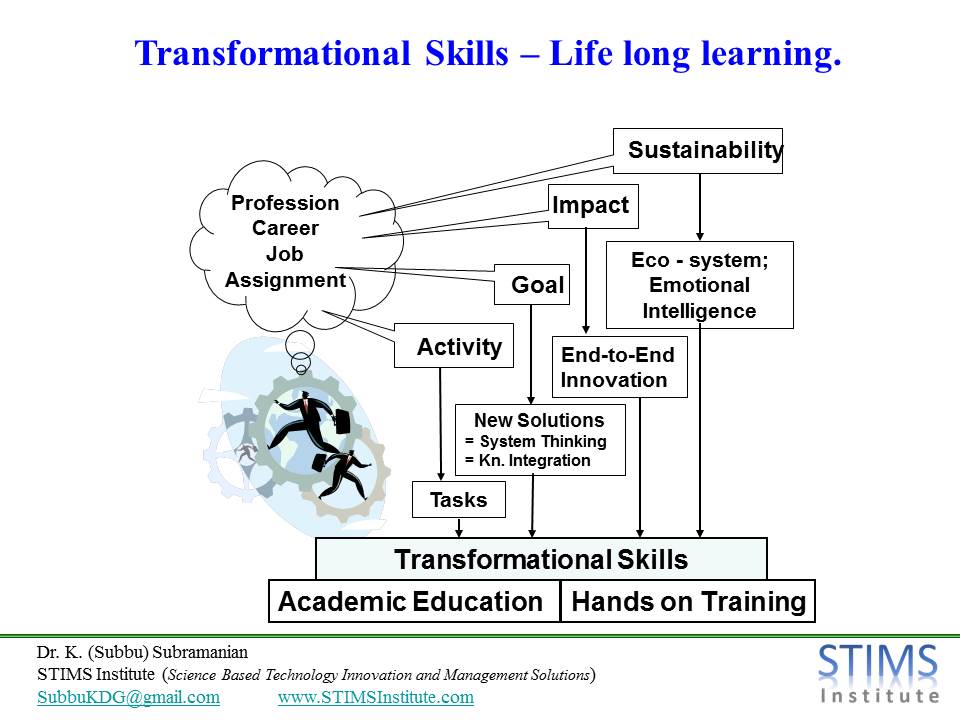

This initiative also involves an innovative program designed to train and foster a few highly competent graduates into future leaders in manufacturing technology through System Thinking and Transformational Skills.

This team works in close collaboration with design, manufacturing and application departments at MGT, with end customers as well as research teams at the innovative University / Industry collaborative R&D center: Advanced Manufacturing Technology Development Center (AMTDC) at IIT Madras, India. Dr. Subramanian, President, STIMS Institute serves as the adviser to AMTDC.

Through the years, these teams at MGT and AMTDC have had several successes many of which are first of its kind for ‘Make in India’. Some of them are unique or novel in the world. The lessons learned from these collaborations are summarized below:

TALENT DEVELOPMENT FOR THE Unique New Solutions (UNS) TEAM:

Recruitment and development of the members for this initiative is rather unique. Individuals, mostly recent graduates, are recruited and assigned to assume a range of responsibilities in a short period of time. The assignments include:

• Market assessment in close collaboration with Sales and Application Engineering to establish the ‘need’ or the customer’s interest and the reason behind;

• Concept development for new solutions as a system, pricing and commercial contract execution;

• Research, Design and analysis of critical sub-assemblies and components;

• Design validation through theoretical calculations using modern tools and methods of FEA/FEM/ Mechatronics as well as advanced software solutions;

• Development of the solution through Concept Validation (establish the ‘science’), Prototype Demonstration (refine the ‘Engineering’), develop the Complete Solution (driven by “Strategy”) and implement at the customer facility;

• Complete ownership in the development of unique products (machines, software, process solutions) from Concept to Commercially Viable Solutions.

Thus, in a short period of a few years, the fresh graduate can grow into a thorough technology professional (with integrated skills across Science, Engineering and Management) in the manufacturing sector. All this shift requires constant training and mentoring on System Thinking and Transformational Skills. This experiment in human resource innovation has been very interesting to say the least! It requires

continuous engagement by the senior management as well as rigorous review and on-line mentoring. Location or time zones are not the barriers for such human resource innovation!

TALENT IS MORE THAN ACADEMIC KNOWLEDGE:

Developing a new solution requires an integration of knowledge across various disciplines. No one person can come with the knowledge from diverse fields such as Manufacturing Processes, Mechanical Engineering, Design, Materials, Electrical Engineering, Instrumentation, Testing, FEA, Mechatronics, Advanced Software

and CNC programming skills. Hence, recruiting the right talent with the required knowledge is a challenge and a starting point.

While graduates from well-known institutions have an edge in the beginning, this advantage is sustained more by those with a passion for continuous learning. After a few years of our experiment we find that true talent resides in those who excel at

three core capabilities: Knowledge, Experience and People skills.

Experience is not to be judged by the years of work in a given job or assignment. Instead it’s gained very quickly by those who are risk takers, willing to experiment with new ideas. Real life validation of their knowledge through working models, prototypes or sales contract builds self-confidence and a true sense of self-worth in young professionals, which is priceless. But this also requires a set of personal skills such as involvement, risk taking, collaboration and a result-driven attitude.

| Core Capabilities of Professionals | Description | Tools or Enablers |

| Knowledge | Deep and extensive learning; Well informed; Comprehension of various aspects of the subject | Formal Education, Reading, Learning from peers, Data driven, searching on-line data base, Observations |

| Experience | Skill derived from actual participation or direct involvement; Accumulated wisdom from real life. | Hands-on Activities, Involvement, Experiments, Risk-taking |

| People Skills | Ability to seek out others and receive their support, help, and cooperation; Willingness to reciprocate, to achieve mutual benefits | Honesty, Integrity, Communication Skills, Collaboration, Team Spirit, Results driven, Emotional Intelligence. |

People skills are those beyond the well-known attributes for inter-personal interactions to get along well with others. In some regards, the people skills we find valuable are grounded in factors such as honesty, integrity and emotional intelligence. These are the skills that not only impel one to personal success, but also helps others and the team to the same outcome.

END TO END INNOVATION:

In most companies, R&D and commercial efforts are run as two parallel silos. One is an internal driven approach where ideas are developed and pushed outside. In other cases it is the sales driven identification of customer needs being pushed into the company for further internal development. Most of the time the internal identified solutions are partial representation of the “system” largely driven by “science” based ideas and their “engineering” refinement. The externally identified marketing driven needs are also partial in that “sales potential” is translated into “engineering” parameters which may or may not be compatible with the internal core capabilities. Hence these partial descriptions of the solution are often incompatible. Also the science and engineering minded professionals show little interest in engaging with the end customers and their needs. Sales and marketing professionals also show little or interest in the graphs, charts and simulations proficient to the technical “experts” inside the company. Our experiment has been to find a seamless blend between the two. Typically, such seamless connection happens in small startup companies. But our goal through UNS and AMTDC is to bring about entrepreneurial teams, talent and outcome while leveraging the resources and facilities of a well-established enterprise and institutions. The talent development for this effort requires education and commitment from everyone, especially the young talented professionals who learn and believe that ‘Every part of the fish has to be alive for the fish to be alive!’.