Customer Success Management (CSM) is a relatively new functional area within many companies, an increasingly vital operational role, a rapidly growing profession, and an underlying systems management philosophy that is growing in importance, especially – but not exclusively – within the technology industry. One leading industry organization (Customer Success Association 2021) defines CSM as “a long-term, scientifically engineered, and professionally directed business strategy for maximizing customer and company sustained business value,”. Others describe CSM as “a customer-facing, non-direct sales role that embodies the mindset of a counselor

to proactively partner with customers to help them achieve their goals and promote long-term customer health that ultimately leads to relationship growth”.

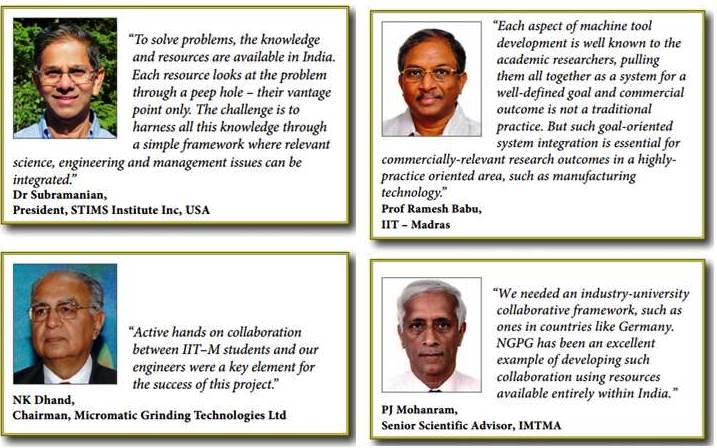

A recent paper that outlines the System Approach for CSM has been authored by Prof. Vijay Merhotra at UCSF, School of Business and Dr. Krishnamoorthy (Subbu) Subramanian from STIMS Institute. For a complete vesrion of this paper, please see: https://stimsinstitute.com/wp-content/uploads/2025/08/system-view-of-csm-published-paper-with-prof.-vijay-merhotra-ucsf-07-22.pdf

Every Co. has processses required to produce and supply their products. When their products are used and the value realized by the customer, only then recurring sales and sustained sales growth of the supplier is realized as illustrated in the figure below:

CSM plays an imptortant interfcae role between the customer and supplier as illustrated in the figure above.

Every process of the “Customer” is a “system” that can be described as an

“Input /Transformation / Output” Scheme

The output itself may be classified as “Technical Outputs” or the nuts and bolts of the solution, leading to the desired value/benefits called the “System Outputs”.

This System Approach has been setailed in the book authored by Dr. Subramanian and Prof. Rangan: https://www.amazon.com/Thriving-Century-Transformational-TechnicalProfessionals/dp/0791860167/ref=sr_1_1s=books&ie=UTF8&qid=1371673516&sr=1-1&keywords=Transformational+Skills+Subramanian

The Customer Success Management as a System integrating customers and Suppliers is illustrated in the Figure below:

In figure 12.3 above on the input side the various functions of the “Customer” and “Supplier” are listed. Everyone of them is a stakeholder in the “Transformation” (i.e.) Customer’s process in which the Supplier’s product is used. Hence opportunities for maximizing or “Optimizing” the System outputs – Stakeholder benefits – could be far larger than that listed even in this figure!

Beyond that, consider all other “Suppliers” involved and their “Products” required for the Customer’s process. Now you have a far larger list of “Stakeholders” and their benefits that you could synergistically optimize and attempt to satisfy. Every such satisfied “Supplier” is also a beneficiary for the “Customer” and his “process”. This a substantially expands the role and impact of “Customer Success Management”!

In this CSM Philosophy, any supplier can adopt the “Customer’s Process” as his own (i.e.) “Becoming a Customer’s Customer”! In many respects it may also be seen as the evolution of Applications Technology in the Customer / Supplier relationships.