Dr. Krishnamoorthy (Subbu) Subramanian, President STIMS Institute has been awarded the coveted 2020 Eugene Merchant Medal offered jointly by two professional Societies (American Society of Mechanical Engineers – ASME; Society of Manufacturing Engineers – SME).

The M. Eugene Merchant Manufacturing Medal was established in 1986 by ASME and SME to honor an individual who has played a significant role in improving the productivity and efficiency of the manufacturing operation. https://www.asme.org/about-asme/honors-awards/achievement-awards/m-eugene-merchant-manufacturing-medal-of-asme-sme

Accepting the award, Dr. Subramanian shared the following brief remarks:

Following is a brief summary by Dr. Subramanian on the highlights of the work that resulted in this prestigious award:

My sincere thanks to ASME and SME. I am very grateful to the awards committee, chairman as well as all my nominators; especially Prof. Jawahir from University of Kentucky. The guidance from my parents and grandparents was the motivation in my early years. Thanks to Prof. Nathan Cook at MIT, Dr. Eugene Merchant and many others for my academic depth and professional approach Special thanks to my family and especially my wife Dr. Durga Subramanian. As a fellow industry professional, as a Chemist, as a mother and grandmother, Durga equally deserves this award! This award is also recognition of the work of a large body of people from Industry and academia from all across the globe. My sincere thanks to all of them.

In the field of Manufacturing, there are countless Physical Processes like Grinding, Machining, etc. They grow their roots through research; become visible through industrial use and yield fruits measured as commercial results. Merchant medal is an honor that recognizes the contribution to this combination of efforts and outcome in manufacturing. I am genuinely honored and humbled to receive this recognition and the award. Thank you very much!

Background:

In a world dominated by computers and Digital Technology one would wonder what is left to do in a 100 or 1000 year old process like Grinding Processes?

Whatever work I did at Norton Co. (and later as part of Saint-Gobain) stand on the shoulders of many others from the long list of researchers in the Norton abrasives Co. family such as: Dr. Loring Coes; Dr. George Reichenbach; Mr. Bob Rowse (who invented Norzon together with Prof. Mert Flemings from MIT); Dr. Richard Lindsey (together with Dr. Hahn from Heald Machine Tool Co.), etc.

The researchers who worked on principles of grinding outside of Norton Family include: Prof. Milton Shaw, his student Prof. Nathan Cook and his student Prof. Steve Malkin and many others. I am also a student of Prof. Cook!

There are also many other eminent researchers from USA, Europe, Germany, Brazil and India among others from across the globe over the years.

Accomplishments:

Seminal work: Microscopic Interaction model : Every grinding process – from manual grinding using Coated Abrasives sanding of furniture or manual weld grinding to precision grinding of every kind to ultra-precision grinding including high tech ceramics manufacturing can be measured, modeled and studied using the “Microscopic interactions model” as the starting framework. https://stimsinstitute.com/wp-content/uploads/2018/01/manu-17-1209-final.pdf Such model is also needed to analyze and manage all modern grinding processes, where abrasive tools are used as Engineered Components as opposed to the traditional approaches where the abrasives have been used as commodity and consumables (and hence any deficiency in the grinding system was compensated by wearing away the abrasive tool!). In this aspect this model is analogous to the seminal work of Dr. Merchant (this award is named after him) and his model for cutting or machining.

This was followed by the drive for in-process data and its accessibility through a portable device that resulted in development of Field Instrumentation System (FIS) and its use. https://stimsinstitute.com/2016/02/16/bringing-the-science-to-shopfloor-manufacturing/ Extensive use of FIS together with the analysis method resulted in many SGA sales people (who were not engineers but technically inclined) become “problem solvers” for our customers. Hence the concept of Application Technology – AT (distinct from Product Engineering) was developed. https://stimsinstitute.com/2012/08/19/vision/

Today in the Bay Area there is a movement called “Customer Success Management” for SaaS Companies. It is almost identical to what we have then called as Applications Technology as a core competence for the hardware and manufacturing sector.

Collectively all of these have enabled for the grinding process to be seen and used more as a science – driven by measurements, data and analysis – rather than as an art.

This was the time of globalization where traditional approaches of selling abrasives in tonnage and price alone were not sufficient. Rather the need was for generation of functional surfaces with added value. This was also the time when Ceramics Grinding in high tech. sector was emerging as a new growth opportunity. This required active collaboration with customers and machine tool builders. While it was like pushing at the end of a rope to move it forward, the System Approach model gave us a frame work for collaboration of many players based on Science and Strategy resulting in several Commercially viable end results for SGA, Customers and Machine Tool builders: https://stimsinstitute.com/2013/04/21/workshop-on-system-approach-to-precision-manufacturing-manufacturing-grinding-processes-june-3-6-2013/ Hence Ceramic Machining Technology Center (CMTC) was born. CMTC was a modest workshop with five or six machines (worth over $2 Million in total on loan from Machine Tool Companies to Norton Co. largely based on mutual trust, technology and innovation) which resulted in many new grinding process innovations, new products and new business for the machine tool partners. For details: https://stimsinstitute.com/wp-content/uploads/2015/06/published-paper-imece2015-52952.pdf This included novel processes for Thin Film Head fabrication in the hard Disk Manufacturing for Data Storage Technology, Machining to Grinding (M2G) processes for aerospace and wind mill gear components, etc.

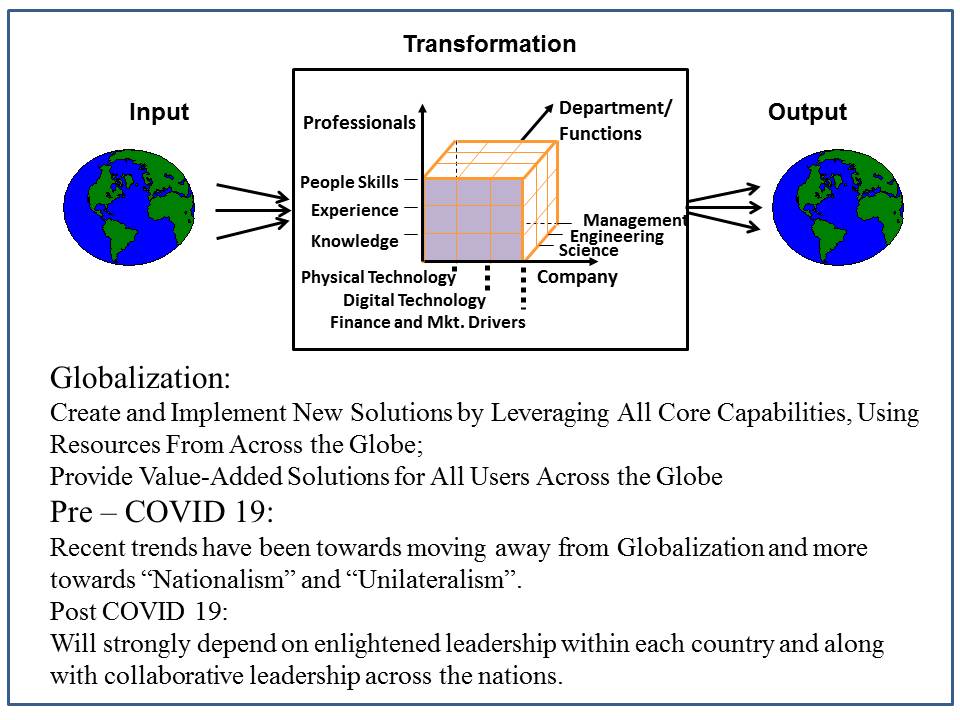

This was also the time of acquisition of 100+ year old Norton Co. of USA by 300+ Year old Saint-Gobain Co. from France. The role of AT, the System Approach and CMTC was recognized as the cutting edge need for success in the Global Economy. These concepts were expanded to all abrasive applications across the globe. The Grinding Technology Centers were set up at many locations in the world (HGTC – USA, EGTC – Germany/ Europe, CGTC – China, India, Brazil, Japan, Australia). These centers have helped to organize and focus Education and Training on AT using the System Approach, International Trainee program, etc. https://stimsinstitute.com/2016/07/21/stims-institute-offers-industry-focused-education-for-fourth-year-in-a-row/ Any technology organization survives based on the commercial impact to the bottom line of the Co. Such commercially valuable outcomes have been achieved across the globe through New Test Methods, New Product and Process development, new markets and business development, new sales approach using AT as a core competence – all focused on Grinding Processes. The emphasis on AT and the System Approach also fostered collaboration across companies and industry/university. All these GTCs continue to function successfully to date, 30 years after they were established! This speaks volumes on the technical foundation and the strategy on which they were established. I summarized the System Approach – A strategy to survive and succeed in the Global Economy in a book published in the year 2000. https://smile.amazon.com/System-Approach-Modern-Machine-Books/dp/1569902550/ref=sr_1_1?s=books&ie=UTF8&qid=1509138730&sr=1-1&keywords=The+System+Approach+Subramanian

This award is the recognition of the collective outcome of many from Norton Co., SGA, their customers, Machine tool builders and other suppliers from across the globe. It is also a reflection of the collective effort and collaboration with many more researchers and faculty from across the globe.

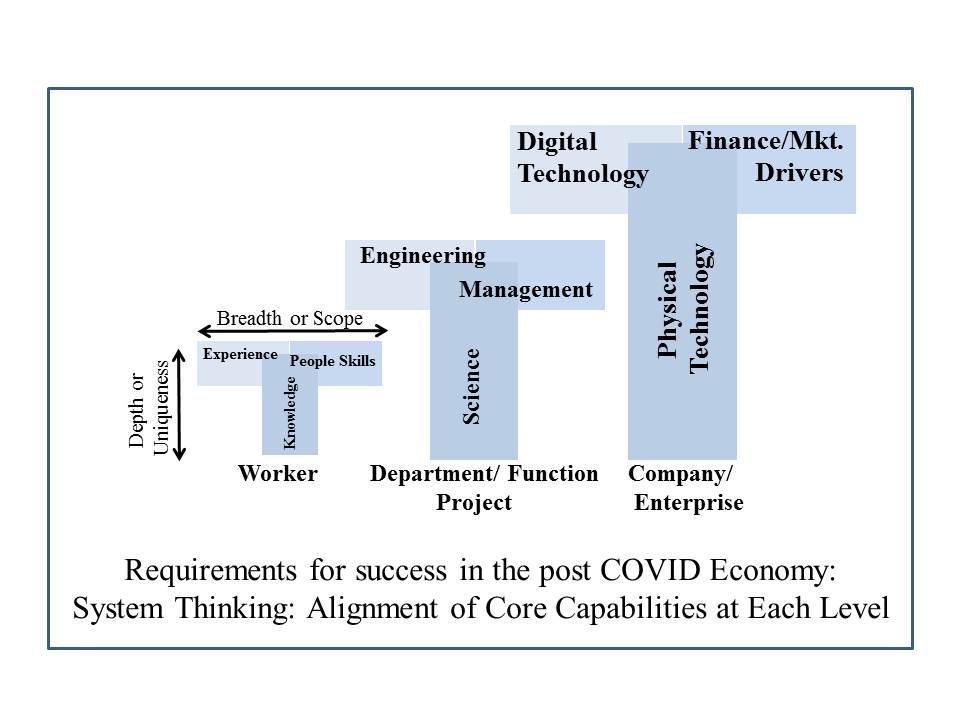

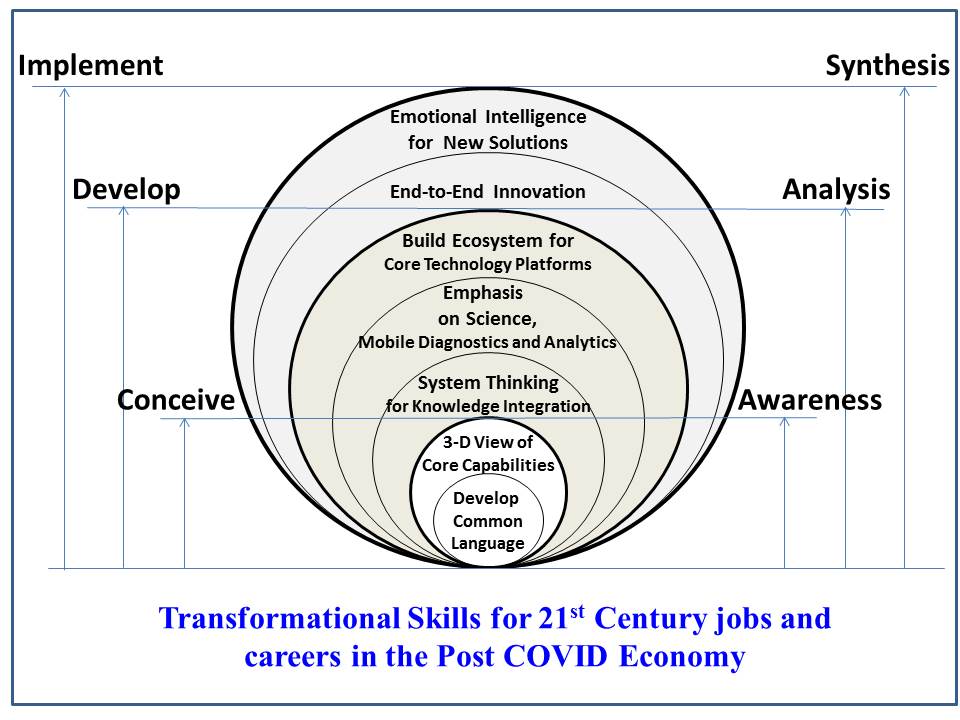

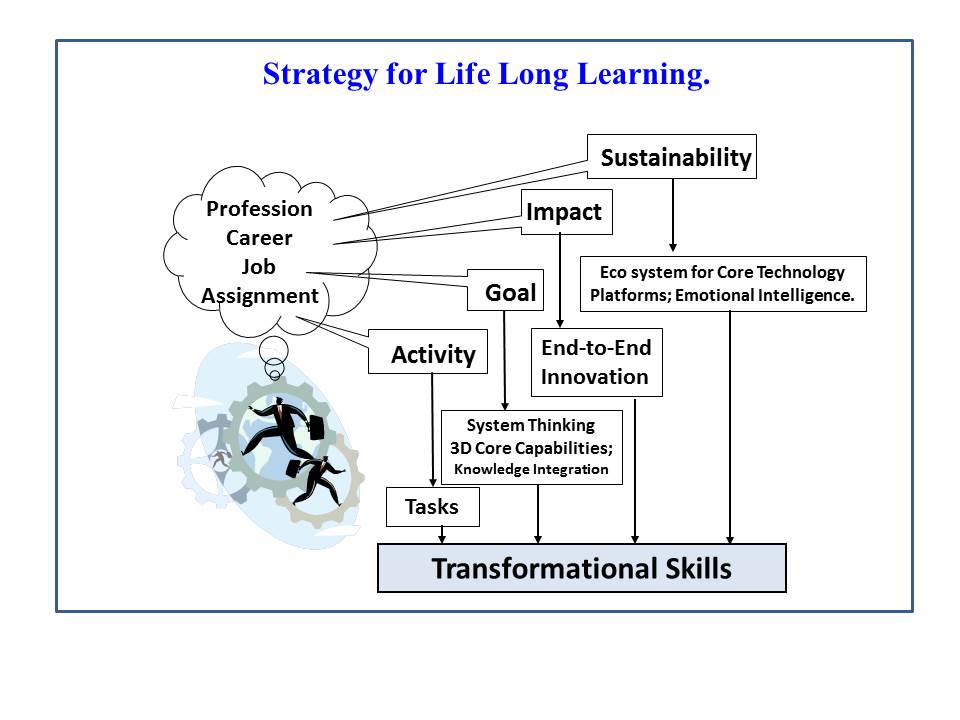

Over the recent years the collaboration with a number of professionals has continued to further document the theoretical models and their application potentials. This time also gave me a chance to compile my thoughts into the second book: Transformational Skills for Technical Professionals, co-authored with a business school professor (Prof. Rangan). http://www.amazon.com/Thriving-Century-Transformational-Technical-Professionals/dp/0791860167/ref=sr_1_1?s=books&ie=UTF8&qid=1371673516&sr=1-1&keywords=Transformational+Skills+Subramanian This book has been published by the ASME Press. https://www.asme.org/products/books/thriving-21st-century-economy-transformational

Dr. Subramanian has expanded the education of the System Approach for Grinding to many locations in India and China. New R&D center for Mfg. Research based on System Thinking and Transformational Skills has been established at IIT – M, for which he is the advisor. https://www.amtdc.org/about/profile/

New Machine tools and hence process innovation have also continued. Some of these outcomes are highlighted at https://stimsinstitute.com/

Now Dr. Subramanian is collaborating with a professor here at UCSF school of Management to adapt many of the AT models for Customer Success Management for software product companies!

Dr. Subramanian is also involved in efforts to integrate basics of philosophy as best practice for success in professional life and modern day management practices: https://www.softpowermag.com/vedanta-for-emotional-intelligence-and-universal-well-being/ More of his essays on Philosophy and its application can be seen at: https://sipractce.wordpress.com/

Looking into the future:

Every one of the items highlighted above is not unique to Grinding Processes. They can be readily adapted for their use in any physical manufacturing process and also for many information processes. It is hoped that this award will serve as a catalyst for such expanded use across many manufacturing and industrial processes of the ideas and methods already proven and validated.

- Any industrial process can be seen and used more as a science – driven by Model, measurements, data and analysis – rather than as an art.

Microscopic Interaction model

2. Portable Instrumentation System and its use at the manufacturing floor with accelerated data science and IoT.

3. Manufacturing, Sales and R&D Engineers acquire proficiency to obtain customer process driven data through sales channels for internal use (in test methods and mfg. rationalization)

4. Application Technology – AT (leveraging end customer’s process and its related know-how, distinct from Product Engineering) to leverage gain through new sales, share gain and higher margins. Today in the SaaS companies in the IT Sector, leveraging Customer Process Know-how for business success is now being developed and managed under the theme of “Customer Success Management”

5. System Approach model as a frame work for collaboration of many players based on Science and Strategy: Collaboration with customers, OEM and other partners for development and implementation of new process solutions.

6. Grinding Technology Centers:

- Education and Training on AT using the System Approach as a frame work

- International Trainee program,

- New Test Methods,

- New Product and Process development,

- New markets and business development,

- New sales approach using AT as a core competence

- — all focused on one or few manufacturing Processes.

7. Collaboration across companies and industry/university.

Largely based on mutual trust, technology and innovation(e.g.): Consignment agreement with OEM; University / Industry Collaboration.